Industrial sterilization: how can you recycle water and energy?

Industrial sterilization: water and energy recovery solutions

Industrial sterilization processes rely heavily on electricity and water. As energy prices rise and natural resources dwindle, the need to find more economically and environmentally friendly alternatives has become critical. Forward-thinking professionals are now looking for more resource-efficient sterilization methods.

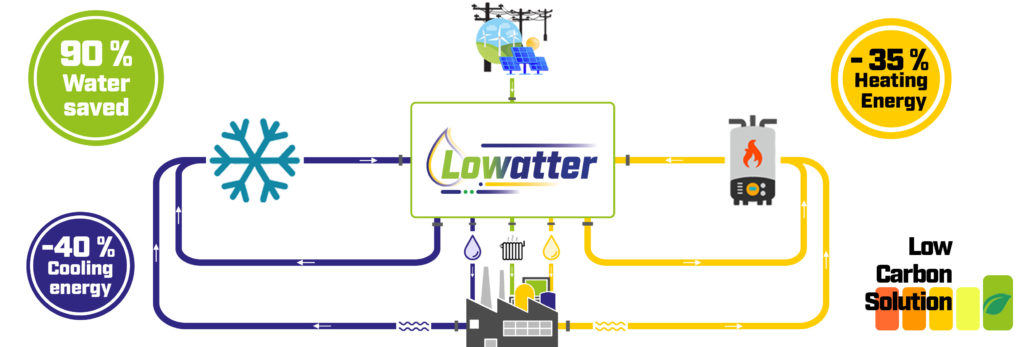

From conventional autoclaves to continuous systems, there are ways to significantly reduce water and energy consumption. One such option is the LoWatter system. This is an efficient recycling device developed by Steritech. It provides savings of up to 40% and can be used with the autoclave or on a plant scale.

Waste energy and industrial sterilization: towards optimization

Whether you are in the food or pharmaceutical industry, the heat generation required for sterilization is a significant consumer of energy and water. This consumption is the result of health regulations and the need to provide safe products to your customers.

In fact, strict adherence to sterilization times is essential in your sterilization processes. At the start of the cooling phase, water can be over 100°C. It contains calories that are unnecessarily lost without a recovery system.

What is wasted energy?

Waste energy is what we now call unavoidable energy. This term encompasses several concepts, including recovered energy. Dissipated energy is the amount of energy trapped in products and water, or lost in production processes. Now well recognized around the world, this lost energy includes:

- unused energy;

- dissipated energy;

- energy that cannot be used as it is.

In your case, waste energy is the energy produced indirectly by the sterilization process. Waste energy can be partially recovered or recycled. It is therefore a very economical energy resource.

From energy waste to energy recovery

According to a 2017 Ademe report, the annual energy potential of industrial waste energy in France is close to 110 TWh. Rejected in the form of heat, this wasted energy represents 36% of fuel consumption. 31% of this energy potential concerns the agri-food sector alone.

The Ademe report also indicates that of this 110 TWh of wasted energy, 48% (52.9 TWh) would be lost at over 100°C. The LoWatter system converts this waste energy into an energy resource. Overall, it helps reduce energy and water waste.

Industrial sterilization: why invest in water and energy recycling?

Installing an energy recovery system like LoWatter in your business offers a number of benefits. It converts waste energy into recovered energy and lowers your operating costs. It also reduces your dependence on external energy resources. With the energy crisis facing the food and pharmaceutical industries, this is a necessary solution.

Technical and financial benefits

A March 2023 report by the Normandy Regional Directorate for the Economy, Employment, Labor and Solidarity indicates that energy costs are one of the main challenges facing the pharmaceutical industry in France.

An article in Libre Service Actualités (LSA) magazine, dedicated to energy prices in the food industry in 2023, makes a similar point. According to its sources, energy prices increased by 57% in 2O22. It adds that 71.43% of the agri-food industry is highly dependent on electricity. For an SME or an industry in the food or pharmaceutical sector, the integration of a water and energy recycling system generates:

- up to 35% savings in heating energy consumption;

- up to 40% savings in cooling energy consumption;

- up to 90% savings in water consumption.

Strategic and ethical benefits

The decision to install this energy optimization system is also a strategic one. It reduces your dependence on energy resources and protects you from any major system disruption. Most importantly, it helps conserve water.

The Water Information Center, in its article on global water challenges, warns of a future explosion in water consumption. It warns of the tensions associated with access to this resource essential to human activity and life. By implementing a water recycling system, your company contributes to a positive change in the world. It also improves its CSR performance.

How does our system for recycling water and energy work?

The LoWatter optimal energy management system is ingenious. It’s a turnkey energy recovery system controlled by a latest generation software. It allows you to monitor energy consumption precisely, by cycles and by products.

Hot water recovery, storage, and reinjection

The principle is simple and efficient. The system recovers hot water from various sterilization cycles. A device returns it to the process according to its temperature. The following list summarizes how it works.

| Sterilization/pasteurization cycle | Temperature status | Energy optimization process |

Start of the cooling cycle | Maximum | Cold water injection on sterilized products |

Cooling | Decrease | Storage of reclaimed hot water in different tanks according to temperature |

Heating | Increase | Re-injection of stored water following the various industrial sterilization cycles |

Customized water and energy recycling system

The LoWatter energy optimization system is customized. The control software determines the optimal configuration for your process. It determines the appropriate energy requirements for each cycle and product. Monitoring provides real-time feedback on water and energy consumption. Excess hot water can be used for other purposes in your plant.

What is the LoWatter energy optimization system?

Water and energy recycling equipment consists mainly of the following components:

- storage tanks;

- intelligent sensors;

- plate heat exchangers;

- motorized control valves.

It’s a package that easily integrates into any autoclave sterilization system. Fully customizable, it is ideal for food, medical and pharmaceutical manufacturers, canneries and small operations.

4-step system integration at your facility

Significant water and energy savings are now possible. The LoWatter system is integrated in four steps:

- audit your process to identify sources of waste;

- study the potential for energy savings and water recycling;

- development of a technical solution tailored to your budget;

- installation of the system in your facility.

Water and energy recycling is a strategic challenge for industrial companies.

Do you want to reduce your energy consumption by up to 40%?

Steritech can provide you with a customized LoWatter system.

Do you have any questions? Contact us by phone or e-mail.