The News

Meet us at IFFA 2025: Steritech welcomes you in Frankfurt Steritech will attend IFFA 2025 in Frankfurt From May 3 to 8, 2025, our team will be glad to welcome you at IFFA, one of the leading international trade fairs for the meat processing and alternative proteins industry. 📍 Hall 8.0 – Booth G98 Meet […]

Goût’stave serving local communities: from April Fool’s joke to real ambition What if our April Fool’s joke became a reality? On April 1st, we launched an initiative both fun and local: installing our Goût’stave autoclave in self-service at the Saverne marina, allowing residents to safely sterilize their own preserves. An exceptional setting, stunning views of […]

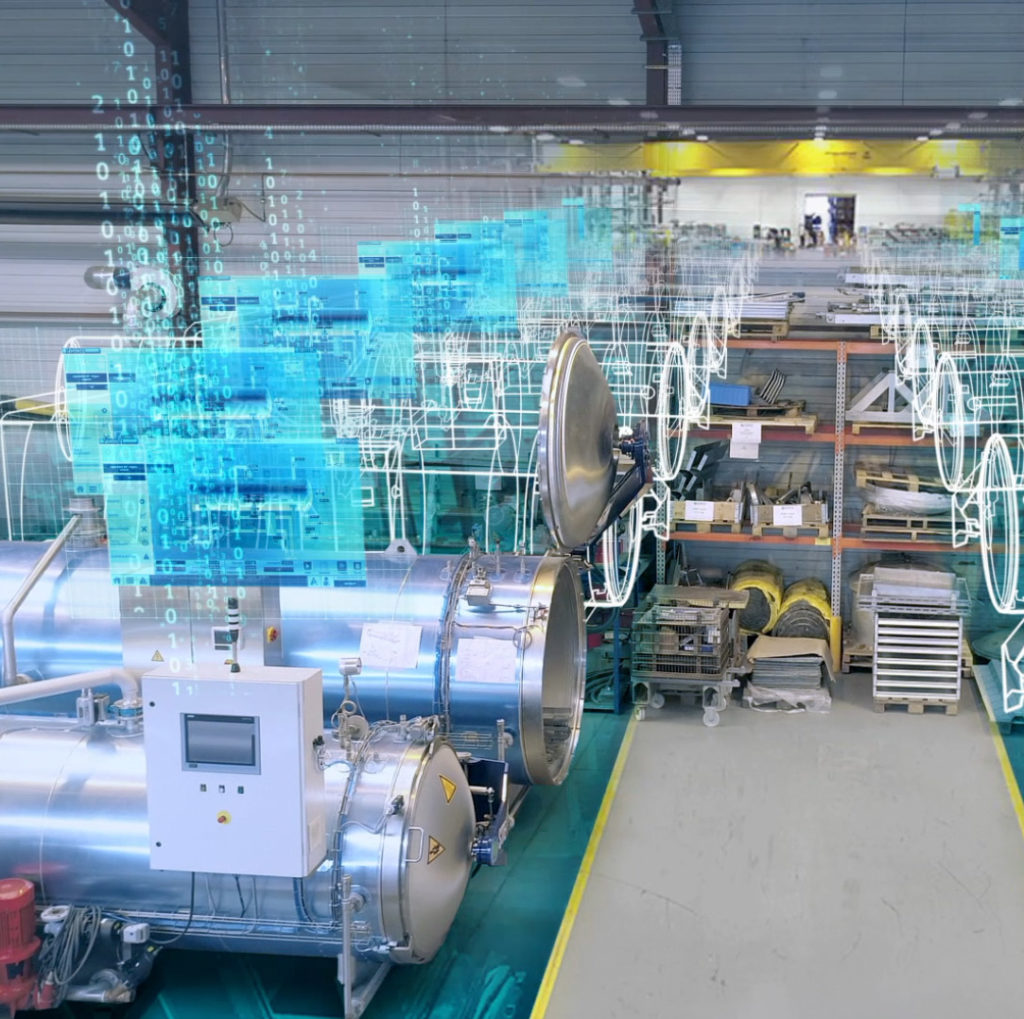

Industry 4.0: A revolution at the heart of industrial production Industry 4.0, often referred to as the “fourth industrial revolution”, represents the integration of advanced technologies into production processes. It’s not just about modernising machines, but completely transforming the way companies interact with their systems, creating intelligent, interconnected factories where every stage of production is […]

📍 Heading for the CFIA, Rennes from 4-6 March We will be present at CFIA 2025 in Hall 5 stand-B26 to present our latest innovations. Goût’stave: the compact and intelligent autoclave for quality production, will also be on the stand. Come and see for yourself! Ideal for canneries and local producers, Goût’stave lets […]

The entire Steritech team wishes you a 𝗛𝗮𝗽𝗽𝘆 𝗡𝗲𝘄 𝗬𝗲𝗮𝗿! 🎉 Looking ahead to 2025, we wish you a successful year full of great opportunities and achievements. We’re always thrilled to support you all around the world and turn your most complex and innovative ideas into reality. With our 𝗶𝗻𝗻𝗼𝘃𝗮𝘁𝗶𝘃𝗲 𝘀𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 that prioritize 𝗲𝗻𝘃𝗶𝗿𝗼𝗻𝗺𝗲𝗻𝘁𝗮𝗹 […]

Personalized services at Steritech for customized sterilization and pasteurization At Steritech, we offer a full range of services to support our customers in their sterilization and pasteurization projects. Whether you want to carry out tests, need advanced software solutions, pilot equipment, rental, used, or retrofit, our experts are here to support you with tailor-made solutions. […]

Presence at PetFair Asia and GulFood Manufacturing 2024 Steritech, a leader in sterilization solutions for the food and beverage industry, is pleased to announce its participation in the international trade fairs PetFair Asia in Thailand and GulFood Manufacturing in Dubai, in partnership with FPT Process & Food Technology, our partner agent. These events will be […]

Botulism in food: preventing risks with Steritech sterilization solutions Botulism is a serious food poisoning caused by a toxin produced by the bacterium Clostridium botulinum. The recent cases of botulism in France in September 2024, following the consumption of pesto jars, are a reminder of the importance of the microbiological safety of artisanal and industrial […]

We are delighted to announce that Steritech will participate this year in SÜFFA in Stuttgart, one of the must-attend events for the meat and processing industry in Europe. Every year, this event brings together professionals from all walks of life – from artisan butchers to large processing companies – to discover the latest innovations, trends […]

Social moments at Steritech : a look back at our recent events At Steritech, we love what we do, but we also enjoy informal times of conviviality between teams. The last few months have been full of events, including a summer barbecue and the inter-company football tournament. 🚀 Afterwork: a time for sharing In […]

Continuous systems: sterilising and pasteurising without interruption for mass production. Discover our 3 unique, high-performance continuous systems. Since 2010, Steritech has been designing dedicated solutions for manufacturers with demanding production and output requirements. These solutions, tailored to your needs, enable you to save a considerable amount of time by speeding up your production […]

Launch of a new project: the carbon footprint A carbon footprint is a way for a company or an individual to assess its impact on the environment and take the necessary measures. In the current climate, the importance of carbon footprints is clear: they are a real tool for limiting greenhouse gas emissions. Sustainable […]

In June, the Steritech team will be participating in several trade fairs, giving you the perfect opportunity to come and meet us in Mexico (Latin America), Korea and Thailand (Asia). Propak Mexico Our Hispanic sales representative will be present at the Propak trade fair in Mexico City from 4 to 7 June 2024. […]

What are the different types of autoclaves? Preserving food and sterilizing medical equipment is an important concern in industry. With the discovery of pathogenic bacteria and microorganisms, the need to sterilize products has become increasingly important, especially in the food and medical industries. There are several types of autoclaves for food and medical sterilization. […]

The Steritech team will be present, from 23 to 26 april, at FHA Food & Beverage in Singapore! The FHA is the first food trade fair in the Asean region, held at the Singapore Expo Park. It gathers retailers, wholesalers and suppliers. 📍Our agent Trinox, with our Sales Director Thierry Lechner, will be […]

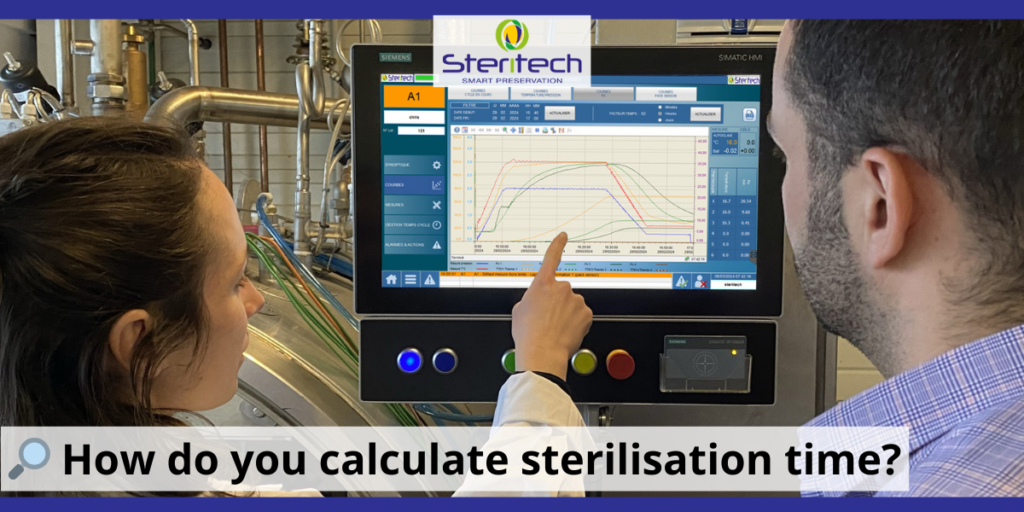

Product sterilization time: how to calculate it? How to calculate sterilization time in industry? Consideration of the time-temperature relationship is essential to ensure proper sterilization. In addition, the use of biological reference indicators is critical. These are a population of microbial that are resistant to sterilization. By measuring the time it takes to destroy […]

Meet Steritech team in Cologne, from 19 to 22 March, at the ANUGA FoodTech trade fair, the international meeting place for suppliers of the food industry! 📍 The Steritech team will be present in hall 10.1 at booth D-050. The Eurostar Machinery team will also be with us during the fair trade to support […]

The 2024 trade show season is underway! 🚀 See you from 12 to 14 March at the CFIA in Rennes, the unmissable meeting point for players in the agri-food industry! 📍 The Steritech team will be present in Hall 5 at booth B26. Come and discover or rediscover our autoclave solutions, Goût’stave, […]

The year 2023 ended with our traditional Christmas meal! This year, the rendezvous was given on the barge symphony of CroisiEurope ! On the agenda: 🩱 A dress code, a chic outfit with a shocking detail on the theme of swimming 🎁 A special Steritech Secret Santa 🥨 A Delicious Meal 🎉 The celebration of […]

Let’s pause and comeback on our main achievements of 2023: 📈 Increased autoclave installations by 84% 🔧 Retrofitted 200% more autoclaves ❤ Great stories with our Goût’stave autoclave 🌍 Expanded our presence to 44% more countries 💰 Achieved an outstanding 18.5% revenue boost 🤝🏼 Embraced 8% new team members 💼 Creation of 5 new positions […]

Dear Steritech customers and partners, We would like to announce that Steritech will be taking a well-deserved break from 25 December to 1 January inclusive for the Christmas holidays. This is the ideal time for our teams to recharge their batteries and celebrate this festive period at family 👨👨👧👦. Thank you for […]

8 reasons to choose a Steritech autoclave control system Do you use an autoclave for medical and surgical materials, products, instruments? Or for food products? And are you wondering about the benefits of an autoclave control system? At Steritech we want to the best for our customers, and our Trilogy control system is first […]

Guidelines of mandatory controls related to the use of an autoclave in 2023 Do you use an autoclave to sterilise food or pharmaceutical products? It’s imperative that you have your equipment inspected to avoid the risk of infection or sterilisation failure. Compulsory autoclave checks are a safeguard for your operators and maintenance staff. An overview […]

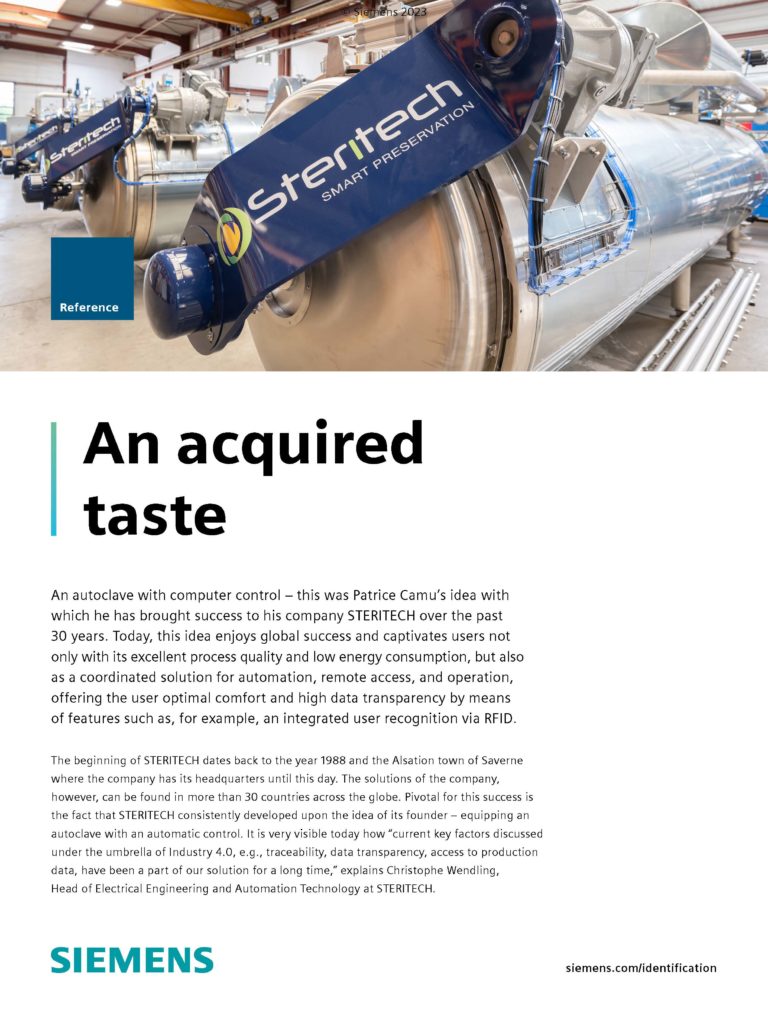

Steritech has been working in partnership with Siemens for many years to push the boundaries of Industry 4.0. In an exclusive interview for Pharma+Food magazine, Christophe Wendling, our Director of Automation and IT, describes how the solutions developed by Siemens bring real benefits to our customers. One of the highlights: the Siemens RFID reader. It […]

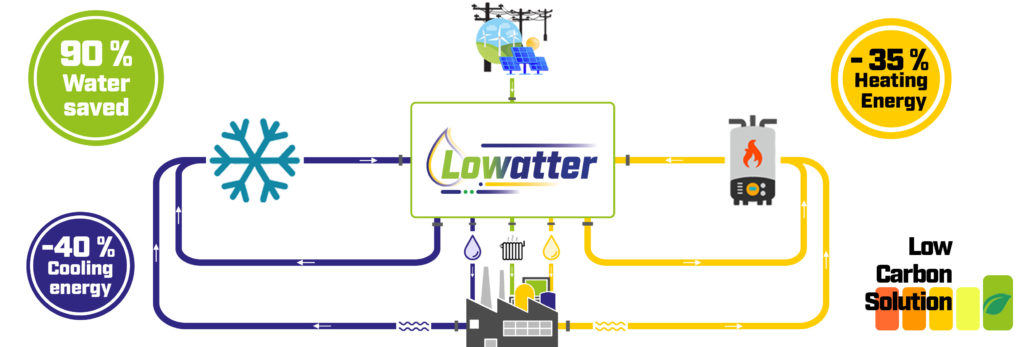

Industrial sterilization: water and energy recovery solutions Industrial sterilization processes rely heavily on electricity and water. As energy prices rise and natural resources dwindle, the need to find more economically and environmentally friendly alternatives has become critical. Forward-thinking professionals are now looking for more resource-efficient sterilization methods. From conventional autoclaves to continuous systems, there are […]

🌏The month of November promises to be rich in meeting once again! Our sales team will be present at two trade fairs with our partner FPT Food Process Technology. GULFOOD Manufacturing Join us in Dubai, from 7 to 9 November, at GULFOOD. We will be present with our partner FPT Food Process Technology. Among all […]

Two very important events will be taking place this month: the Süffa trade fair in Stuttgart, which is the meeting place for small German meat producers, and the Process Expo trade fair in Chicago, which is the meeting place for food processing technologies. So, if you are a well-known company looking to modernize 🖥 your […]

The use of pressurized equipment (PEE) The use of pressurized equipment presents a number of risks. The energy accumulated by the pressure can be very considerable. The sterilization industry, as a regular user of such equipment, is directly concerned. In addition, the operator’s responsibility covers both the operation and the installation. Knowing and complying with […]

A little autoclave for small and medium business owners: For small and medium businesse owners, committed to sustainable food, finding effective solutions for sterilizing and pasteurizing products is crucial. That’s where our Goût’stave comes in. an Autoclave, designed specifically for small-scale operations, Goût’stave offers remarkable advantages in terms of efficiency, flexibility and durability. Goût’stave was […]

What is appertization or canning of perishable foods? Appertization or canning is the process of sterilizing perishable foods in hermetically sealed containers. It was perfected in the 19th century by a French confectioner. This method ensures long-lasting preservation of products. It can be used to preserve vegetables, meat and ready-made meals. But what are the […]

Retrofit in industry: extend the life of your machines Retrofit in the industry is a cost-effective solution for modernizing production machines. By renewing or adding certain parts, this process offers an advantageous alternative to the complete replacement of your machine, giving it a second life. The benefits of retrofitting are numerous: compliance with standards, updated […]

Get your calendars ready! Meet us in Korea! We will be at the Seoul Food & Hospitality ! The show will be held from the 30th of May to the 2nd of June. It is the largest food and hospitality trade show in Korea. We will be there in partnership with Young Dong E&TS. Meet us […]

Looking to discover the latest trends and technologies in the industry? Interpack is the event for you! From May 4 to 10 in Düsseldorf, Germany, more than 3,000 exhibitors from over 60 countries will be present to show their latest innovations in packaging, machinery and associated technologies. Among the exhibiting companies, we are proud to […]

The sterilization of canned food is developing for ecological reasons and to avoid the waste of food products. The market of sterilizers and retorts is rich and varied. Industrialists and artisanal canners can select several types of packaging: bottles, cans, glass jars, etc… Thus, food industry professionals have a wide choice of retorts for jar […]

The 4 steps of the food sterilization process Food sterilization destroys all microorganisms, including spore-forming bacteria. It also extends the shelf life of food. Finally, sterilization reduces the risk of microbiological contamination. Let’s take a closer look at the characteristics and at the 4 steps of the food sterilization process. The sterilization process: characteristics […]

What are the main methods of food preservation? Mankind has found many methods to extend the shelf life of food. Being able to consume produce outside its harvesting period is an undeniable advantage for a balanced, environmentally friendly diet. Various methods are used to avoid food spoilage: water removal, drying, canning sterilization, fermentation, etc. In […]

Come and discover our new products and solutions on our booths in 2023! We will be present for the 26th edition of CFIA Rennes from March 14 to 16. The CFIA is the leading French trade show for suppliers of the food industry, divided into 3 different sectors: Ingredients & Processed food products, Equipment & […]

What equipment should an artisanal cannery have? The growth of the food industry in France is now favored by the return in force of certain types of establishments. Indeed, the “small” company of artisanal cannery seduces more and more. However, each cannery project must be carried out on the basis of a market study. It […]

Steritech’s values #1 Our mission is to support you throughout your project, doing everything possible to offer you the most effective and respectful global preservation solution through our values.🌎 In today’s worrying context, Steritech wishes to take a turn by reaffirming its committed vision. During 2022, we defined the values on which our […]

What are the training courses and opportunities to become a food canner? Since the pandemic, a lot of people are looking to consume with more authenticity and quality. This is especially true when it comes to buying food. To benefit of artisanal products, close to home, is now part of their choice criteria. Are you […]

SIRHA and IPPE trade fairs 2023 is starting strong for Steritech! We will be present at two exhibitions in January! SIRHA Lyon Meet us in Lyon, from 19 to 24 January, at the SIRHA trade fair. We will be accompanying our partner TECHNA, supplier of WECK glass jars. You will be able to discover or […]

Setting up an artisanal cannery: what you need to know to succeed Since the health crisis, the market for artisanal canning has been changing. Customer demand for local and artisanal products is growing. But setting up your own canning business is not easy. In this article you will find a lot of information on how […]

Pasteurization of fruit juices: how does it work? Extending the shelf life of our food products is the leitmotif of the entire food industry. The latter has found a tailor-made solution to offer fruit juices with good nutritional qualities. After the pasteurization of milk, the pasteurization of fruit juices is growing. Find out more about […]

Tailor-made retort At Steritech, for each project, we offer solutions adapted to your needs! Before entering the production process, we analyse your request, your products, your packaging, your environment and your constraints (technical, spatial, financial). Once we have understood your needs, we design equipment that is specially made for you. Our offers are customized for […]

Pasteurization and sterilization – what are the differences? Since the dawn of time, mankind has been working to preserve food in a safe way. The aim has been to invent techniques for eliminating all bacteria and microorganisms that could be harmful to health. In this article, we will describe the two main examples: pasteurization and […]

Congratulations Maxime! Maxime has completed an international training as a welding technologist, over a period of almost 1 year and comes out PROMO MAJOR! The whole team is very proud of him! His evolution inside the company: As a result of his diploma, he is now double-hatted: He still works in the mechanical design office for […]

Team building at Steritech Each year, Steritech organizes activities with the entire team. The objective? To reinforce team cohesion between all departments. For us, having fun and a good time, it’s the way to know each other better. It is therefore essential to get out of the workplace to discover new horizons together while […]

Do you know the job of a boilermaker? At Steritech, the boilermaker has many missions. He cuts, welds, assembles tubes and metal sheets, etc… He anticipates the deformations that can be caused by high temperatures on materials. But he is also in charge of checking and controlling the weld that has been made, to verify […]

6 tips for choosing an autoclave for food sterilization An industrial food autoclave is needed to sterilize and pasteurize food to extend its shelf life. A wide range of food autoclaves is available. They come in different sizes, depending on your needs. You can also choose how your food is sterilized: by water spray, air […]

How does sterilization by autoclave work? Food preservation has always been a concern for mankind. The need to sterilize products has become increasingly important with the discovery of pathogenic bacteria and micro-organisms. It is particularly important in the food industry. This is why heat treatment equipment, such as the autoclave, has been developed. So, how […]

La création et l’optimisation des barèmes de stérilisation et pasteurisation est la clef d’un process réussi ! Pour vous accompagner, découvrez le laboratoire Steritech.

Steritech has been attending trade fairs around the world to present its autoclaves for many years. Every year, we aim to innovate our stand and make it more pleasant for the customers as well as for the salesmen who are present there. Our international presence at trade fairs allows us to meet you and […]

Have you ever heard about autoclaves? Retorts are used for the sterilization and pasteurization of packaged products. These are two methods of heat treatment: sterilization is made at a temperature higher than 100°C, whereas pasteurization is made at a temperature lower than 100°C. Both methods preserve food, by eliminating pathogenic microorganisms. How does […]

Steritech is currently receiving 6 interns! Concerned about investing in students and accompanying them in their professional beginnings, we offer every year internships for all grades, from the discovery internship to the final one. We like to pass on our knowledge to young students, who in return share their knowledge acquired during their studies with […]

Congratulations for the inauguration of the FPT Campus on June 20, 2022, for this special event our sales manager Thierry LECHNER was present. We wish the entire FPT Food process Technology team a lot of success and thank you for our partnership. Have you already heard about the FPT campus technology center? This center is […]

Our employees participated in the “Plein des sens” animation proposed by the Maison de la Nature Bruche et Piémont in Oberhaslach.The day was organized in several sensory workshops to awaken our 5 senses. The touch with a sensory path barefoot in the middle of the nature This type of trail allows us to discover new […]

Do you know the job of industrial machinery installation technician ?🔍 At Steritech, the Assembly and After Sales Service Technician assembles, installs and tests our industrial equipment dedicated to the pasteurization and sterilization of food and pharmaceutical products. He plays both a technical and a relational role with our national and international customers in order […]

Food truck 2022 With the return of the sunny days, we organized a lunch in our offices to spend a convivial moment gathered. We called on the UTOPIA food truck to enjoy good pizzas throughout the meal. 🍕 We love these sharing moments at Steritech because : • It’s a time to exchange with each […]

Filming at Steritech ! In may, a new video was shot in our offices ! This video, integrating all Steritech’s collaborators, was made to allow you to discover our company under a new angle. We wanted to share with you our philosophy of life, our DNA which emanates from the commitments we make through […]

There are less than 2 weeks until the next trade fairs, save the dates ! 📅 EXPO PACK in Mexico City, MexicoWe will be there in partnership with Eurostar Machinery At the same time, you will discover our new autoclave: Goût’Stave, which will cross the Atlantic for you!📅 14-17 june📍Expo Santa Fe, Mexico City, MXStand : […]

Come and meet our team of experts at IFFA trade fair [Hall 8 Stand G98] from 14 to 19 may 2022 ! the world’s leading trade fair for technology for meat and alternative proteins ! Our team will be delighted to support and guide you with your sterilisation and pasteurisation projects. At the same time, […]

SEE YOU at Anuga FoodTec in Cologne, Germany ! 🕑 Victor, THIERRY, Christophe, Christine, Emilia and Pierre, will be there to build with you and answer your sterilisation and pasteurisation projects. From standard or specific machines to complete lines, Steritech takes care of it all. Above all, come and discover our latest innovation: Goût’stave, our small autoclave that has all the features […]

Our team composed by THIERRY LECHNER, Christophe Nicola and Emilia D. is waiting for you in order to support and advise you in the choice of your thermal solution and the development of your products. Come and discover our solutions for food pasteurization and sterilization, as well as our small autoclave Goût’stave, nominated […]

Come and discover our new products and solutions in our stands! – CFIA at Rennes From 08 to 10 March 2022: During 3 days, the CFIA gathers the major food industries and suppliers of 3 different sectors Ingredients & IAPs, Equipment & Processes and Packaging & Packing – ANUGA […]

In edition n° 1398 of January 11, 2022, Process Alimentaire magazine presents an article on reinventing lines and equipment to consume less energy, in which some of STERITECH‘s innovations were cited. Some historical companies have today unchanged processes because they work properly. Is it possible to gain in performance, while having the desired results? […]

🕑Steritech SA is looking forward to seeing you again at the FACHPACK trade fair from 28 to 30 September in Nuremberg. The European trade fair for packaging technology🥫🌍! We will have the opportunity to meet you, to understand your project and to support you in your pasteurization and sterilization projects for food and pharmaceutical, whatever your packaging. 🙋♂️Victor […]

A little history on food preservation techniques 🔎 Do you know why the treatment of food by different processes has always played an essential role in the history of human nutrition ? Initially hunter-gatherers, man was nomadic and had to continually move around to find the food he needed to eat. Later, he […]

Discover the 3 main advantages of steam air autoclaves: : In the autoclave market, we can find different processes of food and pharma pasteurization or sterilization industry, such as water spraying, pure steam, immersion, cascading but also steam air. What is the Steam Air sterilization process ? This process consists in heating the […]

Better sterilize your products, while reducing cycle times : On the one hand, it is necessary to take care of the food safety of the products and thus to guarantee the good pasteurization/sterilization of the products of our customers by respecting the VP (pasteurizing value) or the VS (sterilizing value) necessary. But on the […]

We would like to thank all visitors to the 2021 edition of the CFIA in Rennes, held from June 9 to 11. We hope that you enjoyed meeting us and that we brought you the information you needed. We will not fail to answer your requests and remain at your disposal. The Steritech team

🇫🇷 Cocorico! We owe the invention of the tin can 🥫 to a Frenchman, Nicolas Appert, in 1795. This confectioner was the first to have the brilliant idea of using glass jars sealed with cork, to sterilize food without exposing it to air. And because he sensed the importance of this discovery, he refused to […]

In a report on the FoodTech and AgTech boom published in the respected French newspaper “Libération,” Steritech Executive Board President Pierre Gavignon explains how Steritech developed connected, “intelligent” pasteurization and sterilization technologies. Steritech is the only company in the worldwide autoclave sector to offer this type of digital solution. Our machines are 100% connected and […]

Another autoclave sent, on time, to the pharmaceutical industry!!! We would like to thank all our team and partners, who are fighting everyday against the COVID 19 pandemic, by delivering to our customers, efficient equipment for the sterilization of products already packed.

As a supplier of pasteurization lines of the company SVELTIC, STERITECH was honored by L’USINE NOUVELLE magazine issue of September 19, 2019. INTERMARCHE’s industrial sector is in the process of reformulating its recipes for frozen ready meals to eliminate all aditives ; and STERITECH’s innovative pasteurization solutions naturally play a key role in this strategy. […]

Visit us, booth LS 6869

STERITECH goes green by reusing its non-returnable pallets to create a 100% green relaxation area, and thus enjoy lunch breaks in the sun! At the beginning of June, during a company meal, around good burgers specially prepared for this occasion, the new terrace was inaugurated.

From 4 to 9 may, many people visited us at our stand during IFFA in Frankfurt. As a specialist in innovative pasteurization / sterilization solutions, STERITECH presents its new products : – Presentation of the new Continuous Modular Pasteurizer (CMP) through a specially dedicated video – Presentation of the latest conveyor solutions connecting autoclaves STERITECH […]

The ANUTEC BRAZIL is an international fair booked for the professionals working in subcontracting for the foodstuff industry. It takes place every 2 years in Curitiba. It is an event organized in partnership with the ANUGA FOODTEC in Cologne, which reveals the last trends regarding the packaging of products and food-processing drinks. STERITECH, specialist of […]

STERITECH with SIEMENS WinCC Professional & SIMATIC HMI PRO We invite you to discover this article on their site by clicking the following link. Good reading

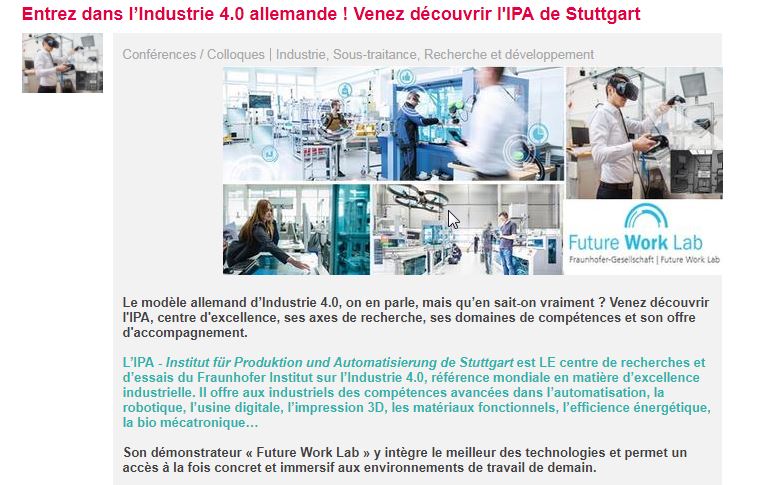

STERITECH a participé au workshop en date du 20/02/2018 à l’IPA de Stuttgart sur l’Industrie 4.0, référence mondiale en matière d’excellence industrielle.

STERITECH is making its autoclaves fit for Industrie 4.0.

He still works in the mechanical design office for 3D design of our sterilisation and pasteurisation solutions.

He still works in the mechanical design office for 3D design of our sterilisation and pasteurisation solutions.

EXPO PACK in Mexico City, Mexico

EXPO PACK in Mexico City, Mexico ProPak Asia in Bangkok, Thailand.

ProPak Asia in Bangkok, Thailand.